Automotive Safety Systems

Our Automotive Safety Systems business manufactures and sells seatbelts, airbags, and interior parts (including electric and nonelectric sunshades, tonneau covers, and separation nets) for automobiles. Our business is global: in the 1990s we expanded overseas and currently have manufacturing and sales bases in seven countries. We contribute to safety, comfort, and peace of mind through improved vehicle performance.

Main Products

Business Overview

New Value Born of Our Founding Philosophy on Safety

At Ashimori, our mission is to ensure safety while providing the comfort that people expect in today’s modern world. In 1962, we were among the first to focus on automobile safety measures and began manufacturing and selling automotive seatbelts. The more comfortable and convenient cars become, the more important it is to ensure safety as well. Solving this challenge requires a strong philosophy on safety backed by exceptionally advanced technology.

Responding to Diversified Safety Needs

In 1967, our Auto Friend brand of car seatbelt acquired JIS (Japanese Industrial Standards) approval, the first such case in Japan. It was later approved under the strict standards of the United States, Australia, and countries in Europe. These achievements were the result of our uncompromising research and development.

In addition to our airbags and related products, we are globally recognized as a comprehensive manufacturer of high-performance, high-quality protection devices that keep car passengers safe. We also contribute to a more comfortable and luxurious car experience by providing valued automotive interior products such as tonneau covers, luggage covers, and electric rear sunshades.

Advancing Technology for Collision Safety

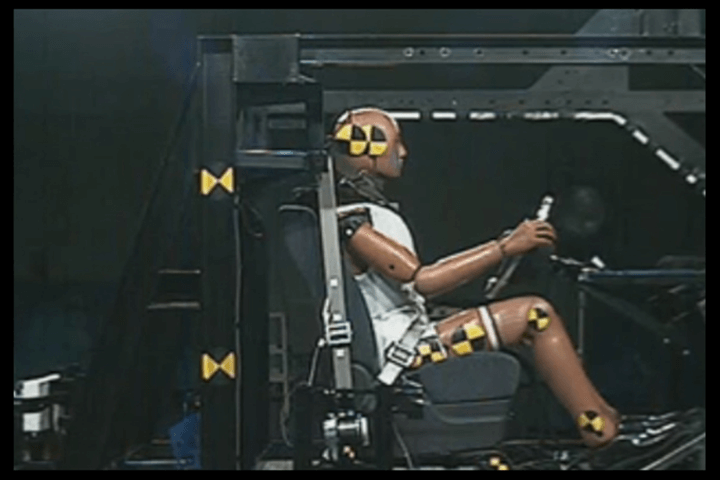

We began manufacturing seatbelts in 1962, and over the years we have adopted testing apparatus that was always state of the art for its time. We have always striven to take a proactive approach to developing collision safety technology.

Using the world’s largest hydraulic-powered crash test machine, we carry out a range of collision simulations, and we are constantly developing new simulation technology. In 2005, we equipped our crash test machine with cutting-edge control units, a modification that made it the world’s most advanced crash test apparatus and allowed us to run even more precise collision simulations and conduct more advanced processing of crash test data.

We have a large number of testing machines, such as the above-mentioned crash test machine, for evaluating the performance of occupant protection devices. Crash test data is gathered from every possible angle and this data is used to conduct virtual collision simulations on computers. The data results are fed back into design and development activities aimed at creating new products. During crash testing, a high-speed camera captures the behavior of dummies in increments as small as 1/1000th to 1/10,000th of a second. This allows us to verify the shape of the airbag cushion and the deployment timing of the airbag.

By continuing to adopt the latest technologies in testing apparatus and push the limits of computer-aided engineering and data analysis, we will make every effort to develop the next generation of car occupant restraint systems.

For Inquiries Regarding Our Products:

Automotive Safety Systems

Sales Department

Automotive Safety Systems

Sales Department