Research and Development

Contributing to Society through Unceasing R&D and Technological Innovation

R&D Areas

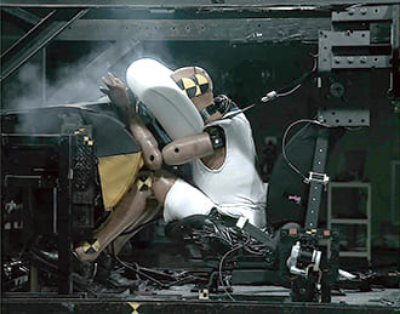

Seatbelts

Airbags

Automotive interior parts

PALTEM

Disaster prevention

Industrial materials

We have established an R&D system that allows us to contribute to society through manufacturing driven by cutting-edge technologies and ideas. We continue to advance this system in targeting the fields of automotive safety systems and high-performance products, including disaster prevention products, industrial materials, and PALTEM.

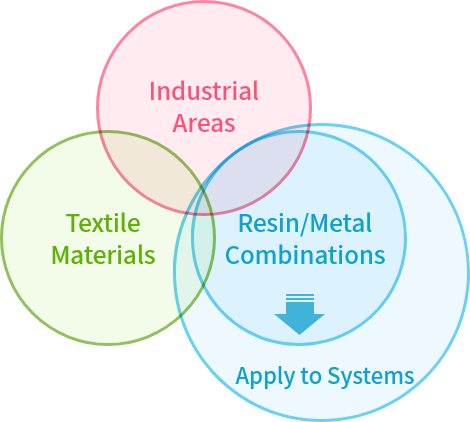

Harnessing Core Technologies to Tap into the Safety and Renewal Market

Combining

By deploying and combining our four core technologies of braiding/weaving, resin (coating) processing, winding/fastening, and inflating, we have developed products ranging from fiber/resin/metal composite components to complete systems. We are engaged in ongoing R&D with the aim of expanding our business in the safety and renewal market.

R&D and Quality Improvement Keep Our Performance and Quality a Step Ahead

Responding flexibly to today’s rapid environmental changes demands a corresponding sense of urgency. In R&D in our Automotive Safety Systems Business Division, we work to improve development speed and accuracy. This is achieved through a combination of data from high-precision test equipment, analysis using computer simulations, and product design that makes full use of 3D-CAD systems. In addition, we are taking on the challenge of delivering products that lead the market in performance and quality by listening to the voices of the market.