Products

Disaster Prevention (High Performance Products Business Division)

Disaster Prevention Materials and Equipment

Products

Disaster Prevention (High Performance Products Business Division)

Disaster Prevention Materials and Equipment

Optimized Mist for the Greatest Fire Fighting Performance.

Excellent for People and the Environment, with Respect to Preventing water Damage

The Jet Firefogging System Series is a mist fire fighting system developed by Ashimori Industry Co., Ltd., and has superior cost-performance characteristics.

With the optimized mist (droplet size of the mist and the water content) produced by the Jet Firefogging System, fire fighting is carried out effectively due to 1) cooling effects, 2) suffocating effects, and 3) dilution effects. With the optimization of the mist, the water-based fire fighting capacity is drawn out to the upper limit; the amount of water used to fight the fire is extremely small compared to conventional large-scale water discharge fire fighting, and it is also possible to fight class B fires.

Of course, this innovative system “prevents water damage”, and achieves ecological fire fighting that is “highly people- and environment-friendly”, non-toxic fire fighting that does not use carbon dioxide or halogens.

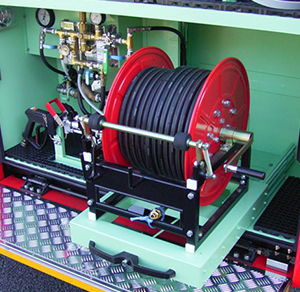

Furthermore, the Jet Firefogging System has a lightweight, compact design that meets the functional requirements for dedicated use in the early stages of fire fighting on light four-wheel fire trucks, and is easily loaded onto rescue vehicles or pump trucks.

Mobile system

Installed on vehicle

1. Optimized Mist with Significant Fire Fighting Capability

2. With One-Step Start-Up and Simple Operation, a Rapid Response to Fires is Possible

3. Designed to Prevent Water Damage, can also Respond to Class B Fires

4. Fires can be Fought in a People- and Earth-friendly Way

5. The Lightweight and Compact Design is Highly Mobile, and a Broad Range of Applications are Possible

Type II nozzle

Straight to wide angle

Variable control

Foam injection via lever

Straight

Wide 30?

Wide 60?

Switchover by lever

| Classification / Mode | Specialized fire fighting pump / High-pressure water transport system / (JF5030) |

||||

|---|---|---|---|---|---|

| Performance appraisal number | Special Appraisal No. 128 | ||||

| Body | Dimensions | 510 × 580 × 932 mm (not including protuberances) | |||

| Weight | 100 kg | ||||

| Pump | Discharge capacity / normal operating pressure |

30 L/min. (4.5 MPa) | |||

| Engine | Manufacturer / output | Mitsubishi / 3.3 kW | |||

| Start-up method | Cell / recoil | ||||

| Discharge nozzle | Weight | 2.5 kg | |||

| Switchover | Straight to wide angle Variable control Foam injection via lever |

||||

| Mist droplet diameter | 110?130 μm | ||||

| Discharge rate | 25 L/min | ||||

| Range | Straight | 15-20 m | |||

| Wide 30? | 8-12 m | ||||

| Wide 60? | 3-5 m | ||||

| High-pressure hose | Outer diameter / working pressure | Outer diameter 18 mm / 14.0 (MPa) | |||

| Storage method | 50 m coil reel | ||||

| Water supply method | 1. Dedicated water suction hose (maximum water suction height 3 m) |

||||

| 2. Supplied from the exterior using a machino coupling | |||||

| Spray of a chemical fire extinguishing foam (Fitted with a foam generator on the nozzle) |

Mixing ratio 3% type, foam amplification ≧6x (synthetic surfactant, aqueous film-forming foaming agent) Note: use wide angle 1 or wide angle 2 |

||||

| Vehicle loading | Object of fire |

|---|---|

| Rescue operation vehicle | Vehicle fire |

| Water tanker | Country fire |

| Light 4-wheel vehicle | Initial stage of the fire |

| Command post vehicle | Initial stage of the fire |

| Ladder truck | Building fire |

Jet Firefogging System beagle

(Jet Firefogging System, mounted)

| Experimental parameters | Lumber, timberwork (dried wood (cedar): edges?3 cm; 90 cm) |

Oil (lamp oil) | Waste tires | Vehicle | |||

|---|---|---|---|---|---|---|---|

| 90 | 180 | 270 | Oil pan 1 m | 5 | 10 | Ordinary automobile | |

| Fire duration (s) | 36 | 56 | 80 | 10-15 | 55 | 125 | 60-70 |

| Quantity of water (L) | 15 | 24 | 34 | 4.2-6.3 | 24 | 52 | 25-29 |

Note: these numerical values are the experimental results for understanding the fire fighting performance, but they are not certified values.

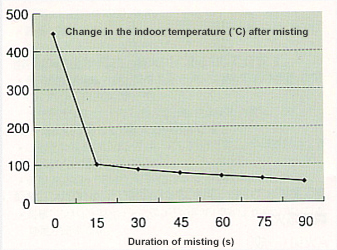

| Test conditions | |

|---|---|

| Test building | Floor space 13 sq.m (3.6 m x 3.6 m) Spatial volume 31 cubic meters (ceiling height 2.4 m) |

| Burning material | Timberwork, dried wood (cedar), 60 pcs, 3 cm x 3 cm x 90 cm |

| Pre-combustion period | 4 min. |

| Misting conditions | Misting carried out from the building windows |

| Misting pressure | 3.0 Mpa |

| Misting rate | 25 L/min |

| Test results | Fire extinguished after 90 s of misting |

Note: temperature sensors were installed in the ceiling inside the room.